The identiPol QA2

The identiPol QA2 is designed to provide unskilled polymer manufacturing and processing staff with a simple tool to identify and assess the quality of thermoplastics.

The identiPol is a quality assurance tool that identifies and assesses the quality of thermoplastics. The system has been specifically designed to provide a quick assessment of incoming material and its suitability for use in production. It can also be used to check manufactured parts. Suitability assessment is achieved by an automated comparison of new batches of material that are compared against known good batches (stored as reference sets) that have been previously tested. This identification, confirmation and comparison of material, together with the MFi value identification (additional software option) allows the identiPol QA2 to offer a complete analysis of incoming and outgoing material.

The QA2 offers an intelligent system that self-optimises test conditions, leaving an operator with only having to enter supplier, material and batch information into the software, before performing a test. Built in diagnostics ensures that samples are always run under optimum conditions and requires no monitoring while the test runs. With this simplicity and automation, running a test and obtaining test results can be performed by inexperienced operators and the total test time is just 15 minutes. This includes sample preparation as well as moulding.

Anything from granulate, flake, powder or pieces cut from finished mouldings can be analysed.

There are three ways in which the QA2 system can be used?

Identification

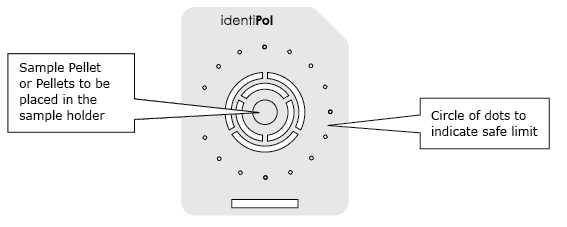

Identifies the type of plastic material the sample is made of from a library of common thermoplastics. This mode allows you to simply identify a material as LDPE, HDPE PP, PA6 PA66 etc. Before the test is run, the sampled polymer (which can be supplied in pellet, granual or powder form) is placed in a Sample Holder for moulding. The QA2 moulds the test sample within the unit, ensuring all samples tested are consistently produced for measurement.

Confirmation

Confirms that the sample is similar enough to previous tests on known good material so that it may be used on the production line with confidence, and assures the continued quality of processed product. A detailed certificate of conformance is produced for the customer.

Comparison

Compares two grades of material for equivalence and reports on their similarity. The Comparison mode can be used to compare a homopolymer against a copolymer as well as comparing different manufacturers or suppliers.

Running a test

Test samples are first moulded within the identiPol to produce a consistent sample for measurement. This is done by placing the patented sample holder into the moulding station, on the left hand side, within the machine. This produces a highly reproducible sample. The sample, typically a granule, is then placed on the sample holder and the lid is closed. The identiPol then automatically moulds the sample by rapid heating at 100⁰C/min. Once moulded into the sample holder the operator transfers the sample to the testing side (right hand side of the testing station) where it is reheated to measure the thermo-mechanical fingerprint of the material. The sample is subjected to a sinusoidal force via a driveshaft incorporating a temperature sensor at its tip. These signals are used to measure the stiffness, loss modulus and temperature difference (delta T) for the sample during the test. These parameters constitute the materials thermo-mechanical fingerprint that will be familiar to the thermal analyst, namely; Stiffness, S’, Tan Delta and Delta T.

The first two parameters come from a dynamic mechanical measurement made using the applied force and displacement sensor within the machine. The Delta T is the temperature difference between the sample and the sensor mounted in the heater block assembly. A number of transition temperatures are also automatically recorded within the system software – e.g. Glass Transition Temperature, Melting Point Temperature and End Point Temperature and are available as a comparative table for all batches of material. They are also matched to a built-in-library of known thermoplastic materials - enabling material identification.

During analysis a thermo-mechanical fingerprint is taken from the tan delta data as a function of temperature and this is stored in a database against the test number. A reference set of known good quality material (ideally from at least three batches) is created. A new batch of material can then be compared against this reference by use of the Quality Index Score (QIS™). 7-10 is the normal acceptance range, but if the score is lower, its specification is probably different and should be investigated.

The QIS™ value is a unique approach developed by Lacerta Technology and The University of Bristol to assess the similarities between test results on different samples. The QIS™ value simply provides an objective assessment and removes operator error in assessing if the most recent test on a sample of material just delivered is comparable and equivalent to earlier deliveries of batches of the same material. The use of the QIS™ value provides a simple, no-quibble, “Go/No Go” as to whether the material is suitable to use on the production line.

What can the identiPol do for you?

Save time

• Prevent incorrect material entering production and resulting issues

• Quick “Go/No Go” decision in the factory regarding material quality assurance

• Ensure production is running at full capacity

Save money

• Reduces the risk of wastage

• Change to cheaper suppliers whilst maintaining product quality

• Potentially reduce insurance premiums

Secure your reputation

• Prevent poor production runs being sent to your customer

• Show your customer a traceable material conformance

• Defend product complaints from your customer

Request a FREE demonstration

We will test your samples and one of our team

will contact you to arrange a demonstration.

QA2 Brochure

Download the digital

QA2 product brochure